TOOL ROOM

This is where all of our tools for injection are created. Everything actually starts from ideas and / or the draft according to the requests of the client. However, the user defines the layout of the desired product, while the construction of the injection tools is made by our toolmakers that have many years of experience.

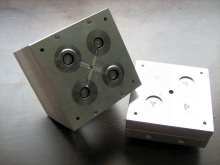

The very design of tools depends on the users' requirements: the required quantity of product, number of cavities in the tool, visible or invisible inlet, refined surface finish, molding material, the weight of the finished product ... to name just a few parameters. After completing the construction of tools, the production of individual parts is started according to the drafts. Our tools are manufactured on modern CNC processing centres to ensure maximum accuracy and longevity of the tool (of course, while respecting recommended maintenance measures). Some parts of the tool must be processed with erosion (EDM), which you can find out more about in the side frame.

When all parts are finished, the tool is assembled. It is mounted on the injector, in order to verify the full functionality of the tools and obtain the test patterns presented to the client.

We can turn any idea quickly and properly into a tangible product. You just need to contact us with confidence. It is desirable that in addition to the ideas you also have and the draft (at least preliminary), preferably in a 3D model in one of the standard 3D CAD formats. The rest is all up to us.

Guided by the high quality standards, we have satisfied customers from across the European Union, and the products manufactured in our facility with their help, can be found in all world markets.

boniplast.hr

boniplast.hr

boniplast.hr

boniplast.hr  boniplast.hr

boniplast.hr